JBMETERS Ltd also has the specialist MV Transformer factory start-ups. This includes the facilities and training to transfer technology, knowledge and expertise to allow existing manufacturers to upgrade their factory or allow investors and business to enter the transformer market and establish their own factory.

JBMETERS offer a full range of services including; feasibility studies, meter design / customisation, project conceptualisation, equipment procurement, component procurement, local training, quality control services and marketing/customer support. Although the preferred approach is the gentle immersion into technology over time, commercial considerations such as import duties often force a deeper technology start up. For greater detail of the services available for a factory start-up please refer to the information given in the Electricity Meter factory start-ups.

Transformers have a vital role in electrical systems as they are a means of “stepping down” the current/voltage in a system to measurable values. We would enable you to manufacture transformers from 10Kv up to 33Kv. Countries in the Middle East, Asia, Africa & South America are shifting from consuming products to manufacturing.

Tests on voltage transformers and current transformers (needed to meet certain standards)

- Accuracy tests – This is to determine whether the errors of the voltage transformer are within specified limits.

- Dielectric insulation tests

- Temperature rise tests

- Circuit tests

- Verification of terminal markings and polarity

- Etc.….

JBMETERS is able to offer a wide range of services for a Transformer factory start-up including:

Feasibility Studies

This study will rationally uncover whether your project is viable. There are many aspects to investigate including; technology and system, operational and schedule feasibility. The results from the feasibility studies will be detailed in a feasibility study report. The feasibility study report will detail the evaluation criteria, the findings and our recommendations.

Transformer Design

We can tailor the design of the transformer to your individual requirements.

Transformer Standards

We can make sure that you manufacture the transformers to international standards.

Production

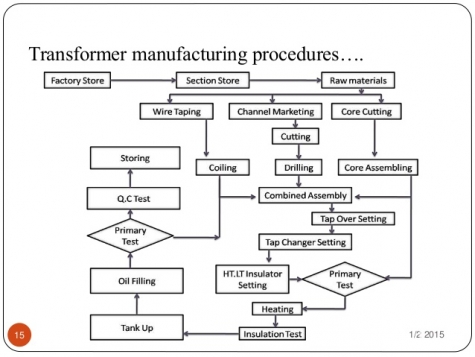

We will assist in identifying all the processes/stages required for water meter manufacturing and therefore we can determine the best design/layout of the factory and the equipment that you will require.

Testing and Calibration

Testing and Calibration will be required to ensure that the transformers are working and that they are functioning correctly. The calibration equipment required will vary depending on the type of transformers that are being manufactured.

Quality Control

We will implement quality control procedures throughout the transformer manufacturing process to ensure certain standards are met.

If any of the transformers at any stage fail to meet these rigorous requirements, the transformer will be sent to the repairs department.