With chip manufactures offering design kits, the concept that a meter factory is an easy process, fails to highlight the practical problems of technology transfer. Problems with design kits include completing manufacturing processes/techniques, incorporating local anti-tampering features and environmental conditions. Named brands of meters offer licence factory technology transfers, which is often beyond the commercial reach of smaller markets / investors.

KIGG has a tried and tested process that reduces the risk factor of these processes. Thus reducing costs, unforeseen liabilities and uncertainty factor associated with a factory project. We will support you throughout this process enhancing your success, including if required business development support, marketing, exhibition, promotions and customer relations.

KIGG with its lower overheads and many years of experience can offer a technology transfer at commercially viable prices. There are many potential problems with the traditional route as you are required to pay loyalties to the licence company. Furthermore, it can be difficult to redesign/modify the meter and you are reliant on the licenser. KIGG’s approach solves these problems and also allows the customer to have their own meter brand.

A full range of services are available including; feasibility studies, meter design / customisation, project conceptualisation, equipment procurement, component procurement, local training, quality control services and marketing/customer support. Although the preferred approach is the gentle immersion into technology over time, commercial considerations such as import duties often force a deeper technology start-up. KIGG has the skills to carry out IEC 62059-41 (2003) : Electricity metering equipment - Dependability-Reliability prediction, which can be independently certified by for example KEMA.

Manufacturing processes

SKD (Semi knock down), CKD (complete knock down) and SMT (Surface mounted technology) are the standard solutions available. SKD is the gentle approach where the factory simply assembles the parts together (Testing and Calibration). It can therefore be seen as a more suitable approach for companies which are new to the industry.

SMT production line

Once a factory start up is complete it becomes possible to expand in the future. For example building the components yourself and eventually move to the SMT level. KIGG will guide you through these processes in stages, allowing you to build up your expertise. The next logical step up from a SKD is carrying out the manufacturing of the housing locally and our injection moulding machine (KIGG-M3) is ideal for moulding the meter base, top and bottom covers. KIGG with its wide experience in metering is also able to offer professional mould design services. Injection Moulding Machine (KIGG-M3).

As mentioned earlier KIGG provides a full range of services for factory set-ups and greater detail of these services is given below:

Feasibility Study

A full feasibility study can be provided, including commercial and technical aspects in order that the viability of a project may be determined.

Design and Development

Our in-house development team are supported by a research project with Glamorgan University, so that both today’s and tomorrow’s solutions can be provided.

Project Conceptualisation

A full project document including drawings, component lists, assembly and calibration procedures can be created so that a reference guide exists.

Equipment Procurement

Compatible, and tried and tested equipment is a key aspect of an efficient factory operation. With KIGG’s expertise in meter testing equipment, we are well placed to ensure that the cost effective and efficient solutions are available.

Component Procurement

With a broad network of suppliers KIGG is able to offer meter kits or key components at cost effective prices.

Quality Control / Inspections

Qualified inspection teams are available for both high volume and high technology factory acceptance tests (FAT).

Training services

Our team of experts are able to offer training in all aspects of the factory production process and supervise a factory start up until such a time that the local staff have confidence.

Marketing/customer support

We are able to offer our expertise by assisting you to find work for your factory. For example we can visit local utilities with you.

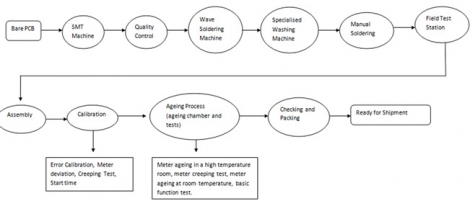

Production Flow Chart for electricity meters

Below is a flow chart which summarises the main production processes required for a manufacture to produce electricity meters (Single and Three phase)